|

China Plate Heat Exchange Co., Ltd

|

Heat Exchanger Plates Heat Exchanger Plates

| Place of Origin: | Beijing, China (Mainland) |

|

|

|

| Add to Basket | Add to My Favorites |

| HiSupplier Escrow |

Product Detail

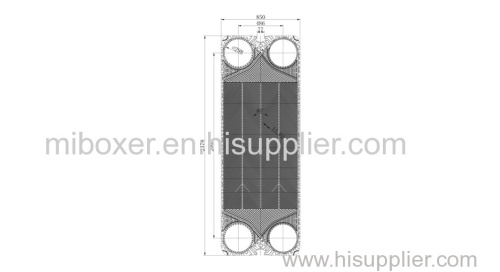

Features of FUNKE Heat Exchanger Plates

Heat exchanger plates are the key components in plate heat exchangers. These plates are designed with specialized patterns or corrugations to maximize heat transfer efficiency. They provide a large surface area for heat exchange between fluids, ensuring effective and efficient thermal performance in various industrial applications.

Types of Heat Exchanger Plates

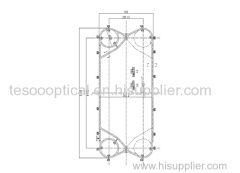

Alfalaval Heat Exchanger Plates

Alfa Laval heat transfer plates are specifically designed plates used in Alfa Laval plate heat exchangers. These plates are made of high-quality stainless steel or titanium to ensure durability and corrosion resistance.

APV Heat Exchanger Plates

APV heat exchanger plates are specialized plates utilized in APV (Aurora Plate and Vessel) plate heat exchangers. These plates are meticulously engineered to facilitate efficient heat transfer between fluids.

Tranter Heat Exchanger Plates

Tranter plates feature unique patterns, such as chevron or herringbone, which enhance heat transfer efficiency by creating turbulent flow and maximizing the contact surface area.

Advantages of Heat Exchanger Plates

01

Thin and Flat Components

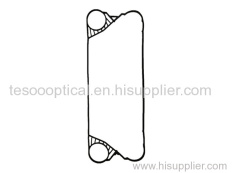

Heat exchanger plates are thin and flat components typically made of materials like stainless steel, titanium, or nickel alloys. They are arranged in a stacked configuration, with alternating channels for the two fluids involved in the heat exchange process. The plates are sealed together using gaskets or brazing to ensure that the fluids flow through their respective channels without mixing.

02

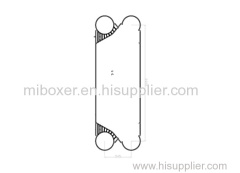

Specially Designed Patterns

The plates have specially designed patterns, such as corrugations or chevron-shaped patterns, which serve several purposes. First, these patterns increase the effective heat transfer surface area, allowing for efficient thermal exchange. Second, they create turbulence in the fluid flow, disrupting laminar flow and enhancing heat transfer by promoting better mixing and minimizing the formation of boundary layers. This turbulent flow helps maximize heat transfer rates between the fluids.

03

Plate Material

The choice of plate material is crucial in heat exchanger plate design. It depends on the specific application and the properties of the fluids being processed. Different materials offer varying resistance to corrosion, fouling, and high temperatures, ensuring the plates can withstand the operating conditions.

What Does a Heat Exchanger Plate Do?

A heat exchanger brazed plate is a crucial component in a plate heat exchanger, and its primary function is to facilitate efficient heat transfer between two fluids. The plate acts as a barrier between the fluids while allowing heat to be exchanged between them. Here's a detailed explanation of what a hot water heater plate does:

Heat Transfer Surface

The plate provides a large surface area for heat exchange to occur between the two fluids. The fluids flow on either side of the plate, with one fluid passing through the channels formed by the plates' corrugations or other specialized patterns. The extensive contact area between the fluids and the plate allows for effective heat transfer.

Turbulent Flow Promotion

The design of the heat exchanger plate, such as the corrugations or chevron-shaped patterns, promotes turbulent flow in the fluid streams. Turbulence disrupts the laminar flow, ensuring thorough mixing of the fluids and minimizing the formation of stagnant boundary layers. Turbulent flow enhances heat transfer efficiency by maintaining a greater temperature gradient across the plate surface.

Separation and Thermal Insulation

The boiler heat exchanger plate separates the two fluids, preventing direct mixing while facilitating the transfer of heat between them. Gaskets or other sealing mechanisms around the edges of the plates ensure fluid separation and prevent leakage. Additionally, the plate and the gaskets provide thermal insulation, minimizing heat loss through conduction between the fluids.

As a heat exchanger plate manufacturer, heat exchanger plate supplier, we will do our best to meet all the needs of customers.

There are many plate heat exchanger suppliers in China, but we are one of the best choices for you.